10 Fabrication Technologies for Acrylic Mirror Sheet

Ukusetshenziswa kwezibuko ze-acrylic kuyanda futhi kubanzi, ingabe uyazi ukuthi yini ubuchwepheshe obuyinhloko bokukhiqiza amashidi esibuko se-acrylic?

I-DHUA njengomkhiqizi ochwepheshe weshidi lesibuko sepulasitiki lapha ibala lobu buchwepheshe obulandelayo bokwenziwa kwezibuko eziyi-acrylic.

I-Saw cutting, inqubo yokusika i-router

Uma sithola i-oda langokwezifiso elinesidingo esicacisiwe somdwebo, sizosika amashidi esibuko se-acrylic ngokuhambisana nezidingo zemidwebo yekhasimende.Sivame ukubiza le nqubo yokusika njengento yokuvula, sebenzisa amathuluzi okusika noma imishini, njengommese we-hook, i-hacksaw, i-coping saw, ama-band saws, i-tablesaw, i-jigsaw kanye ne-router, ukusika ishidi lesibuko se-acrylic ngobukhulu obucacisiwe nobujamo ngokusho imfuneko yekhasimende.

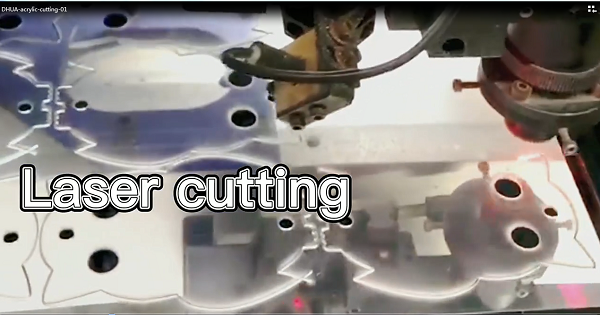

Inqubo yokusika i-laser

Uma kuqhathaniswa nomshini wokusika ojwayelekile, umshini wokusika we-laser ubonakala ikakhulukazi ngokusetshenziswa kwe-laser cutting, ukuzuza ekongeni isikhala, ukonga indawo yokusika, nokusika kalula ngokusho kwemidwebo, zonke izinhlobo zezithombe zokusika, ngisho nesithombe esiyinkimbinkimbi, ukusika akunankinga. .

Inqubo ye-Thermoforming

I-Acrylic njenge-thermoplastic inikeza inzuzo ukuthi singayakha kalula futhi siyinikeze ukuhlukahluka okuhlukahlukene kobumo.Okudingayo nje ukushisa okuthile.Le nqubo siyibiza ngokuthi i-thermoforming, eyaziwa nangokuthi ukugoba okushisayo.

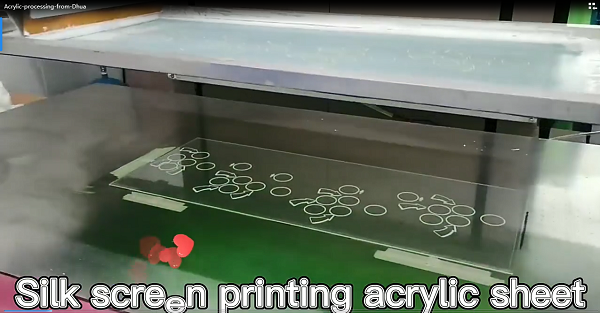

Inqubo yokuphrinta isikrini

Ukuphrinta isikrini kuyinqubo yokudlulisa uyinki ku-acrylic substrate ngokusebenzisa anezikhala, kusetshenziswa i-squeegee/roller ukugcwalisa izimbobo ezivulekile.Ukuphrinta isikrini nge-acrylic kusetshenziswe kabanzi ezintweni ezenziwe ngezinto ze-acrylic.Ungaphrinta umbala ogcwele, izithombe zekhwalithi yesithombe, amalogo kanye nombhalo ngokuqondile ezibukweni ze-acrylic.

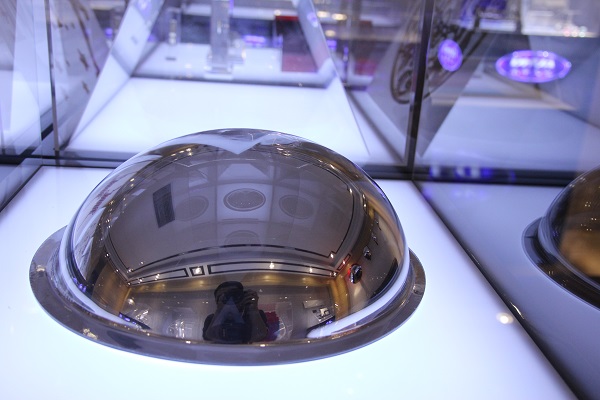

Vuthelaukubumba pi-rocess

Inqubo yokubumba i-Blow iwuhlobo lwenqubo ye-thermoforming, indlela ngokuyinhloko ngokushaya.Ngemuva kokwelashwa kokushisa, ishidi le-acrylic lishaywa i-hemisphere ngobukhulu obudingekayo, bese lilungiswa ukubunjwa ngesikhunta.

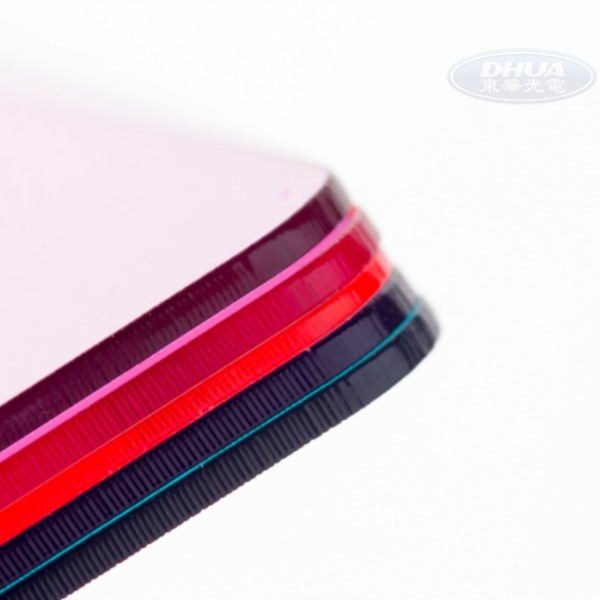

Gukuhlanza kanye ne-polishg inqubo

Ukugaya nokupholisha kuyinqubo ngemva kokusika ishidi lesibuko le-acrylic noma ishidi le-acrylic.Ngemva kokusika, unqenqema lwesibuko lungase lube lukhuni, kanti ezinye zizobangela umphumela omubi wokubuka.Ngalesi sikhathi, sidinga ukusebenzisa amathuluzi wokupholisha ukupholisha okuzungezile kweshidi le-acrylic, silenze libe bushelelezi ngaphandle kokulimaza izandla futhi silenze libukeke liphelele.

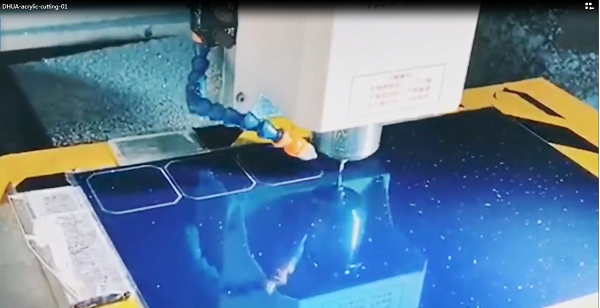

Inqubo yokubaza

Ukuqopha kuyinqubo yokukhiqiza/yokwenza ekhiphayo lapho ithuluzi likhipha impahla kucezu lokusebenza ukuze likhiqize into yomumo oyifunayo.Kulezi zinsuku, inqubo yokubeka imigodi ngokuvamile yenziwa irutha ye-CNC okuwumshini wokusika olawulwa ngekhompiyutha onesisiki esinamathiselwe ku-spindle ejikelezayo ukuze wenze inqubo yokusika.

Inqubo yokumba

I-Acrylic drilling ibhekisela endleleni oyisebenzisayo ukudala izimbobo ku-acrylic material ukuze ufeze izinjongo ezahlukene.Lapho umba i-acrylic material, uzosebenzisa ithuluzi elivame ukubizwa ngokuthi i-drill bit, elibuye lihluke ngobukhulu.Ukumba i-Acrylic kuvamile ezimpawu eziningi, imikhiqizo yokuhlobisa, izinhlelo zokusebenza zefreyimu njll.

I-vacuum coatinginqubo

Isibuko se-Acrylic senziwe ngeshidi le-acrylic elicutshungulwayo ngokuqhubekayo bese lenziwa kusetshenziswa inqubo ye-vacuum metalizing, lapho ishidi linikezwa isibuko esiqediwe esisekelwa ukunamathela okuqinile okuvikelayo.Ngomshini wokuhlanganisa i-vacuum, singenza amashidi esibuko se-acrylic anezinhlangothi ezimbili, i-acrylic esobala ebonakala ngesibuko, amashidi esibuko se-acrylic azinamathelayo.

Inqubo yokuhlola

Ngaphandle kokuhlolwa okuyisisekelo okubonakalayo, nokuhlolwa kobude, ububanzi, ukujiya, umbala kanye nomphumela wesibuko seshidi lesibuko le-acrylic, kunokuhlolwa okwengeziwe kochwepheshe ukuze kuqinisekiswe ikhwalithi yamashidi esibuko sethu se-acrylic, njengokuhlolwa kokuqina, Ukuhlolwa okungagugi, ukuhlolwa kwe-chromatic aberration. , ukuhlolwa komthelela, ukuhlolwa kokugoba, ukuhlolwa kwamandla okunamathela njll.

Isikhathi sokuthumela: Nov-17-2022